Engineering

Experience and skills of our engineers allow us to implement elements into production basing on received technical documentation or design product from the beginning – range of engineers works depends on Customer’s expectations. The latest CAD / CAM software allows us to bring about improvements and savings already in the design phase of the device. During serial production, together with the Customer, we are looking for solutions to reduce costs, eg. by optimizing material usage. While working on the project and during the production process, we focus on continuous improvement, affecting the improvement of the quality of the final product and profitability.

In subsequent stages of production, our designers work closely with engineers to meet all Customer requirements and to anticipate and resolve potential problems.

Basing on this we elaborate and implement innovative solutions into the production process.

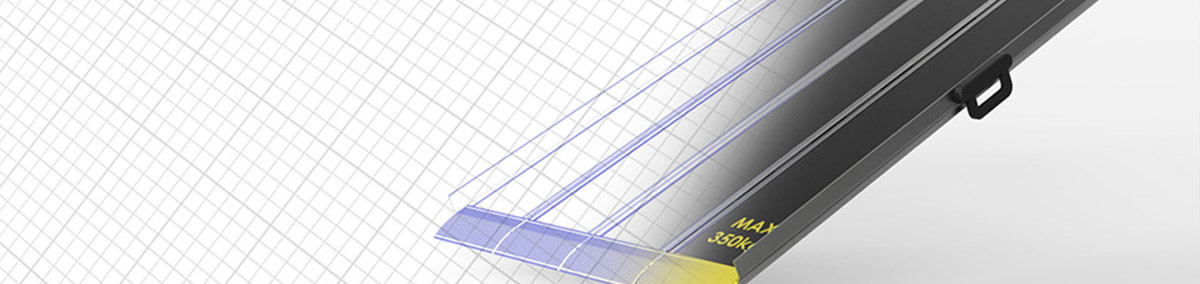

MECHANICAL DEVICES, MACHINES PARTS DESIGN USING CAD ENVIRONMENT

- 3D MODELLING,

- GENERATION OF ASSEMBLY DOCUMENTATION,

- GENERATION OF OPERATING DOCUMENTATION,

- RESOLUTION OF TINWARE CONSTRUCTION PARTS,

- ERGONOMIC ANALYSES,

- REALISTIC VISUALIZATION,

- CREATION OF FINAL VIRTUAL PRESENTATIONS (AVI,MPEG),

- RENDERING OF IMAGES,

- PRESENTATION OF ELEMENT ASSEMBLY AS A PRESENTATION OR FLAT DOCUMENTATION,

- DRAWING PROJECTS IN 2D DXF, DWG FORMATS FOR CAM DEVICES.

AUTOMATICS AND ROBOTICS

- DESIGNING OF CONTROL SYSTEMS,

- PLC CONTROLLERS PROGRAMMING,

- DIAGNOSIS AND REPAIR OF CONTROL SYSTEMS.

CUSTOMIZED PROJECTS

Apart from the production of products for the rail vehicle market, our

dynamically developing branch of activity is the implementation of dedicated

advanced design solutions in CAD systems.